How to define the dimensional accuracy of precision stamping parts?

The dimensional accuracy of precision stamping parts refers to the difference between the actual size of the stamping part and the basic size. The smaller the difference, the higher the dimensional accuracy of hardware stamping parts.

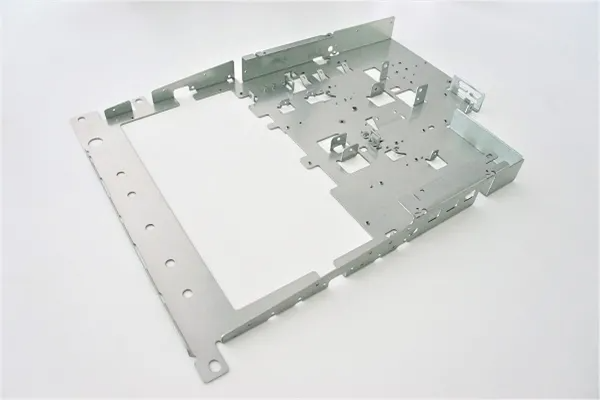

Precision stamping parts - Chengruifeng

The dimensional accuracy of precision stamping parts is measured by tolerance registration. According to the national standard, it is divided into 20 levels, from IT01, IT0, IT1, IT2 to IT18. The larger the number, the lower the tolerance level (machining accuracy), the larger the allowable range of size variation (tolerance value), and the smaller the machining difficulty.

The dimensional accuracy of stamped parts can generally be divided into two categories: precision level and ordinary level. Precision level refers to the precision that can be achieved in stamping technology, while ordinary level refers to the precision that can be achieved through more economical means. When the precision of mold manufacturing is high enough, the precision of the outer dimensions of precision stamping parts can reach ITl0 level, and the inner hole size can reach IT9 level.

The factors that affect the dimensional accuracy of precision stamping parts in the production process include: the manufacturing accuracy of hardware stamping molds; Hardware stamping die assembly process; Elastic recovery of materials after stamping; There are also other accidental factors in the production process, such as inaccurate positioning and unstable material performance, which can affect the dimensional accuracy of hardware stamping parts. Therefore, if you want to produce stamping parts with high dimensional accuracy, you need to consider these aspects.

If you are looking for related products or have any other questions, please feel free to call our sales hotline at any time

National unified sales hotline:86 514 85906288

01??Message Consultation(Equipment, output, price, materials, processes, etc)

02??Waiting for a follow-up visit(Quick response within 30 minutes)

03??Free customization(Free customization of process plans according to needs)

Want to know the price? Production? Model? After sales? Please leave a message and we will reply to you as soon as possible

MESSAGE

在線客服

在線客服